Pneumatic diaphragm pump is an industrial pump operating on the basis of compressed air power. Compressed air is made from air compressor and is compressed into a container

In industries, diaphragm pumps are not too strange. However, for newly converted to use, it is difficult to remember that name. It is also quite difficult to operate this device without understanding what it is? How does it work? What is it used for? The following article will help you understand the basic operating principle of the diaphragm pump to achieve the highest efficiency of use

Pneumatic diaphragm pump is an industrial pump operating on the basis of compressed air power. Compressed air is made from air compressor and is compressed into a tank. Therefore, the use of pneumatic diaphragm pumps is easy and safe, less explosive incidents occur.

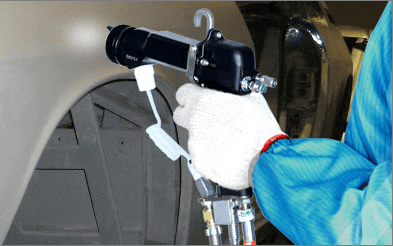

However, during use, it is also necessary to maintain the device periodically to reduce the damage caused by the working environment or due to an unintended incident. In addition, some diaphragm pumps are often used to pump paint in wooden workshops, ceramic workshops, ... Garage cars, so some people are also known as paint pumps. Also do not mistake it as a paint spray gun as used in other industries

* How to operate of the diaphragm pump

Before we know how to maintain diaphragm pumps, we need to know the principle of the diaphragm pump, to avoid unfortunate incidents and waste time, effort and money when the machine is suffering from the machine. broken.

To know how the diaphragm pump works we look at the picture below. First, look at the compressed air valve in addition to supplying compressed air into the left chamber, creating a diaphragm pushing pressure to the left. Under this pressure, closing valve 1, opening the valve 2, allowing the liquid to be pumped.

Next, the figure below we look over the compressed air valve besides providing compressed air into the left chamber, creating the pressure to push the diaphragm to the left facing out. Under this pressure, closing valve 1, opening the valve 2, allowing the liquid to be pumped. The right pump is also moved in the same direction to the left side through the connection axis. Create vacuum pressure closed valve 4 and open valve 3, absorb liquid into the storage chamber to prepare for the next cycle. End of cycle 1.

We continue to see the compressed air valve in addition to supplying compressed air into the right storage chamber, creating a diaphragm pushing pressure to the right outward. Under this pressure, closing valve 3, opening the valve 4, allowing the liquid to be pumped. The left pump is also moved in the same direction to the right side through the connection axis. Create a vacuum shirt to close the number 2 valve and open the valve 1, absorb the liquid into the storage chamber to prepare for the next cycle. Coming here, ending cycle 2.

The pumping process continues through the number 1 cycle.

For 2 input products with 2 different types of chemicals, the activity of the pump is still the same. Chemical 1 goes through Valve1, chemical 2 goes to valve 3. And is mixed in the ratio of 50/50 at the output - this ratio depends on the viscosity of the chemical

The material and structure of the diaphragm pump are very diverse, suitable for many chemicals and solutions of different solutions.

Address: Room 0705, 7th Floor, Luxury Park Views - D32 Cau Giay New Urban Area, Yen Hoa Ward, Cau Giay District, Hanoi, Vietnam.